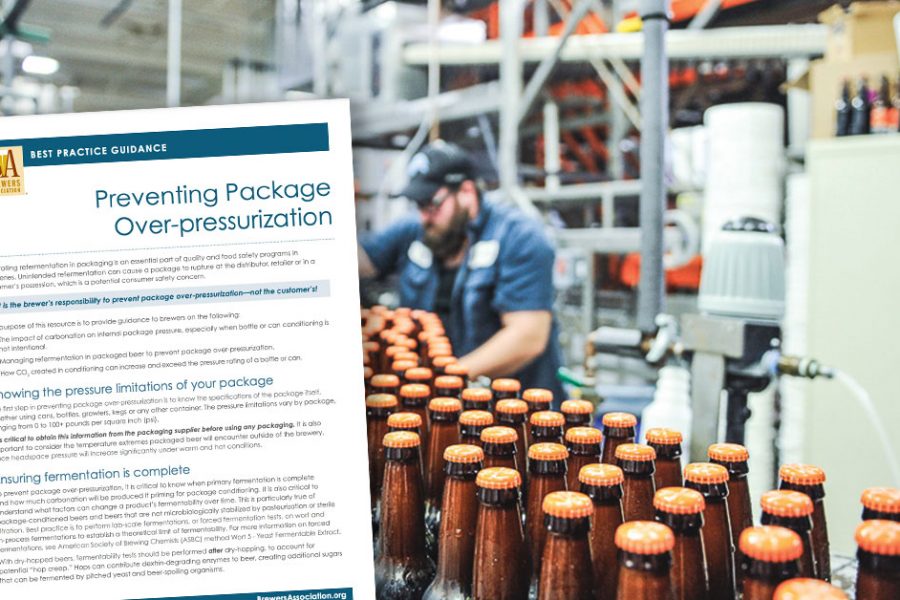

Preventing Package Over-Pressurization

It is the brewer's responsibility to prevent package over-pressurization. This resource guides brewers on how manage this potential consumer safety concern. Read More

You are using an outdated browser not supported by The Brewers Association.

Please consider upgrading!

Whether you’re packaging your beer in kegs, cans, or bottles, it’s important to make sure that you’re doing it right. The resources in this section will help you reduce beer loss and package your beer to maintain freshness until it reaches the glass.

It is the brewer's responsibility to prevent package over-pressurization. This resource guides brewers on how manage this potential consumer safety concern. Read More

Learn about the main factors impacting beer freshness during packaging and how to monitor and improve beer freshness with a quality control checklist.Read More

Link to author biography

Link to author biography The Quality Subcommittee envisions a membership that consistently produces beer of high quality. Quality for this purpose has been defined as: a beer that is responsibly produced using wholesome ingredients, consistent brewing techniques and good manufacturing practices, which exhibits flavor characteristics that are consistently aligned with both the brewer’s and the beer drinker’s expectations.

See Quality Subcommittee's Articles

This seminar addresses concerns about bacterial survival in low- or non-alcohol and low-hopped beers during pasteurization. Learn about the basics of microbial death through heating and the impact of pasteurization on beers, including those with reduced alcohol and hops.Read More

Discover how to successfully incorporate pasteurization processes into your food safety and quality control plans.Read More

Link to author biography

Link to author biography The Quality Subcommittee envisions a membership that consistently produces beer of high quality. Quality for this purpose has been defined as: a beer that is responsibly produced using wholesome ingredients, consistent brewing techniques and good manufacturing practices, which exhibits flavor characteristics that are consistently aligned with both the brewer’s and the beer drinker’s expectations.

See Quality Subcommittee's Articles

This series provides resources on oxygen-monitoring methods and sensors and how to mitigate oxygen during brewing, cellaring, and packaging.Read More

Link to author biography

Link to author biography The Quality Subcommittee envisions a membership that consistently produces beer of high quality. Quality for this purpose has been defined as: a beer that is responsibly produced using wholesome ingredients, consistent brewing techniques and good manufacturing practices, which exhibits flavor characteristics that are consistently aligned with both the brewer’s and the beer drinker’s expectations.

See Quality Subcommittee's Articles

Understand the pasteurization unit (PU) calculation, equipment used, validation points, factors affecting PUs, and safety considerations.Read More

Link to author biography

Link to author biography The Quality Subcommittee envisions a membership that consistently produces beer of high quality. Quality for this purpose has been defined as: a beer that is responsibly produced using wholesome ingredients, consistent brewing techniques and good manufacturing practices, which exhibits flavor characteristics that are consistently aligned with both the brewer’s and the beer drinker’s expectations.

See Quality Subcommittee's Articles

Learn about the three unique sensor technologies used in the measurement of dissolved oxygen in beer: optical, polarographic, and galvanic.Read More

Link to author biography

Link to author biography The Quality Subcommittee envisions a membership that consistently produces beer of high quality. Quality for this purpose has been defined as: a beer that is responsibly produced using wholesome ingredients, consistent brewing techniques and good manufacturing practices, which exhibits flavor characteristics that are consistently aligned with both the brewer’s and the beer drinker’s expectations.

See Quality Subcommittee's Articles

Oxygen plays many roles during various stages of the brewing process, but preventing the pickup of oxygen from the end of fermentation is key.

This introductory resource will provide background on beer freshness, oxidations, and how to make practical process improvements.Read More

Link to author biography

Link to author biography The Quality Subcommittee envisions a membership that consistently produces beer of high quality. Quality for this purpose has been defined as: a beer that is responsibly produced using wholesome ingredients, consistent brewing techniques and good manufacturing practices, which exhibits flavor characteristics that are consistently aligned with both the brewer’s and the beer drinker’s expectations.

See Quality Subcommittee's Articles

Recent activity in state and federal recycling-focused legislation has the potential to impact small craft brewers.Read More

Link to author biography

Link to author biography The Sustainability Subcommittee serves the Brewers Association purpose by helping current members and future generations to brew the highest quality beers in a manner that strengthens the value of our businesses, increases the resiliency of the natural environment and agricultural systems that provide brewing ingredients, and enhances the lives of our workforce and the communities we call home.

See Sustainability Subcommittee's Articles

Download this cheat sheet on detecting and managing mousy off flavors, also known as "THP," by the Brewers Association Quality Subcommittee.Read More

Link to author biography

Link to author biography The Quality Subcommittee envisions a membership that consistently produces beer of high quality. Quality for this purpose has been defined as: a beer that is responsibly produced using wholesome ingredients, consistent brewing techniques and good manufacturing practices, which exhibits flavor characteristics that are consistently aligned with both the brewer’s and the beer drinker’s expectations.

See Quality Subcommittee's Articles Resource Hub

Resource HubExplore the Brewers Association's most high-value resources and tools in one click. Need some additional guidance? Click here to setup a resource meeting with Graham, the BA's Engagement Coordinator.

Finish setting up your membership at the link below!

Renew now to keep accessing exclusive seminars, industry statics, the BA forum, and much more!

Please contact our membership team to evaluate your profile.