Supply Chain Updates

This harvest estimate update includes info on the barley and hop harvests, CO2 shortages, transportation, and cardboard and aluminum prices.Read More

You are using an outdated browser not supported by The Brewers Association.

Please consider upgrading!

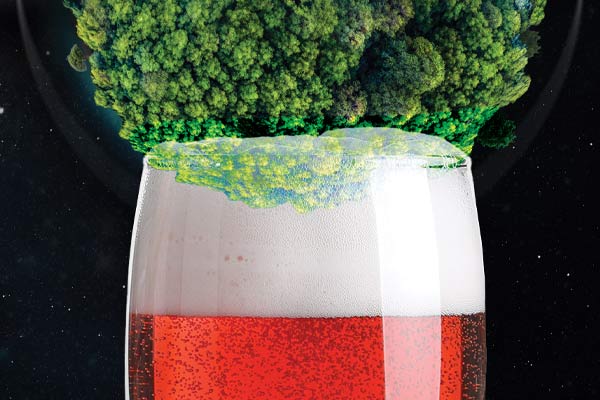

We all know the basic ingredients in brewing beer: barley, hops, water, and yeast. Learn all about these ingredients, including where and how to get them, what equipment to use to store and handle them in your brewery, and how to maintain and analyze their quality to make the best beer possible.

This harvest estimate update includes info on the barley and hop harvests, CO2 shortages, transportation, and cardboard and aluminum prices.Read More

Link to author biography

Link to author biography The Supply Chain Subcommittee is concerned with the ingredients and materials that are used to brew and package craft beers. By monitoring hop and barley harvest, interacting with growers and examining packaging supplies, and monitoring glass and can markets, the Supply Chain Subcommittee works to ensure a stable marketplace and provide educational resources to the brewing community on best practices for sourcing and selecting ingredients and packaging materials to suit their beers.

See Supply Chain Subcommittee's Articles

Learn if performing hop selection remotely rather than in person makes sense for you, and know all the do's and don'ts for success.Read More

Link to author biography

Link to author biography The Supply Chain Subcommittee is concerned with the ingredients and materials that are used to brew and package craft beers. By monitoring hop and barley harvest, interacting with growers and examining packaging supplies, and monitoring glass and can markets, the Supply Chain Subcommittee works to ensure a stable marketplace and provide educational resources to the brewing community on best practices for sourcing and selecting ingredients and packaging materials to suit their beers.

See Supply Chain Subcommittee's Articles

When it comes to improving brewhouse efficiency, taking a simple initial approach to the malt Certificate of Analysis (COA) is helpful. Read More

Link to author biography

Link to author biography Katie Fromuth is the Technical Brewing Projects Manager for the Brewers Association. Prior to this role she held the position of Quality Lab Director with the Fermentation Science and Technology program at Colorado State University and as Quality Lab Manager at Oskar Blues Brewery, Longmont. She received her Bachelors of Science in Environmental Health (2012) and Masters of Science in Horticulture concentrating in agricultural chemistry (2022) studying the impacts of package type on beer chemical stability. She holds a General Certificate in Brewing from the Institute of Brewing and Distilling, completed the Advanced Class in Craft Malt Production, and served as an instructor for the American Society of Brewing Chemists (ASBC) Deep Dive into Quality course. From her love of this industry she’s been involved with both the ASBC Technical Committee and Master Brewers Association of the Americas Rocky Mountain District board for almost a decade. She's passionate about communicating the science and art of brewing and fermentation to spark in others curiosity and joy towards the fantastic world of fermentation.

See Katie Fromuth's Articles

Ensure your brewery is getting the most value per pound of CO2 by using our calculator and comparing your use to your peers.Read More

Link to author biography

Link to author biography The mission of the Maintenance and Engineering Subcommittee is to develop and enhance the craft brewing community's preparedness related to equipment and other technical aspects of building and maintaining a brewery.

See Maintenance and Engineering Subcommittee's Articles

Download this cheat sheet on detecting and managing ethyl acetate, written by the Brewers Association Quality Subcommittee.Read More

Link to author biography

Link to author biography The Quality Subcommittee envisions a membership that consistently produces beer of high quality. Quality for this purpose has been defined as: a beer that is responsibly produced using wholesome ingredients, consistent brewing techniques and good manufacturing practices, which exhibits flavor characteristics that are consistently aligned with both the brewer’s and the beer drinker’s expectations.

See Quality Subcommittee's Articles

The Supply Chain Subcommittee provides a long view, deep dive into three key ingredients used to produce beer—hops, barley malt, and carbon dioxide (CO2).Read More

Link to author biography

Link to author biography The Supply Chain Subcommittee is concerned with the ingredients and materials that are used to brew and package craft beers. By monitoring hop and barley harvest, interacting with growers and examining packaging supplies, and monitoring glass and can markets, the Supply Chain Subcommittee works to ensure a stable marketplace and provide educational resources to the brewing community on best practices for sourcing and selecting ingredients and packaging materials to suit their beers.

See Supply Chain Subcommittee's Articles

Optimize CO2 usage by performing system maintenance and conducting audits to keep business running smoothly and reduce costs.Read More

Link to author biography

Link to author biography The mission of the Maintenance and Engineering Subcommittee is to develop and enhance the craft brewing community's preparedness related to equipment and other technical aspects of building and maintaining a brewery.

See Maintenance and Engineering Subcommittee's Articles

By tracking brewhouse efficiency with this simple calculator, brewers can ensure you're not leaving any money in your mash tuns.Read More

Link to author biography

Link to author biography The Brewers Association Technical Brewing Projects Team has over 50 years of craft beer industry experience and works alongside the Technical Committee to promote access to raw materials; support research and advances in sustainability, education, technology, and raw materials; foster a commitment to holistic safety, quality, and operational excellence; support the well-being and a sense of belonging of the people of the craft brewing community; and promote sustainable operational practices that enhance environmental stewardship. The team comprises Chuck Skypeck, Technical Brewing Projects Director; Katie Fromuth, Technical Brewing Projects Manager; and Adriana Terrón, Technical Brewing Projects Administrative Specialist.

See Technical Team's Articles

Metallic off-flavors in beer arise from metal ions that can come from several sources, including brewery equipment and some raw materials.Read More

Link to author biography

Link to author biography The Quality Subcommittee envisions a membership that consistently produces beer of high quality. Quality for this purpose has been defined as: a beer that is responsibly produced using wholesome ingredients, consistent brewing techniques and good manufacturing practices, which exhibits flavor characteristics that are consistently aligned with both the brewer’s and the beer drinker’s expectations.

See Quality Subcommittee's Articles

The hop plant (Humulus lupulus) is highly susceptible to climate-induced environmental changes. Key measures are currently underway to ensure its long-term survival.

To meet customers' insatiable thirst for hoppy beers, most breweries are dry hopping, which increases the risk of costly beer loss from eruptive hop volcanoes and even costlier worker injury. Check that you're dry hopping like a pro. Remember, DRYHOP.Read More

Link to author biography

Link to author biography The Safety Subcommittee increases safety awareness of Brewers Association members with the goals of minimizing risk and preventing harm to people, products, and facilities.

See Safety Subcommittee's Articles Resource Hub

Resource HubExplore the Brewers Association's most high-value resources and tools in one click. Need some additional guidance? Click here to setup a resource meeting with Graham, the BA's Engagement Coordinator.

Finish setting up your membership at the link below!

Renew now to keep accessing exclusive seminars, industry statics, the BA forum, and much more!

Please contact our membership team to evaluate your profile.